O&E Technologies Sdn Bhd

|

|

Environmental Division

|

|

|

Environmental Planning

|

|

|

- Environmental site assessment

- Feasibility and due diligence

- Integrated environmental development planning

- Management plans

- Solid and scheduled waste management

- Emergency Response Plan (ERP)

- Sustainable development assessment

- Green technology solutions

|

|

|

|

Landuse and Socio-Economics

|

|

|

- Social impact assessment (SIA)

- Site selection studies

- Pollution inventory

- Terrain analysis and landform studies

- Land capability studies and feasibility studies

- Landuse planning and management

- Cost-benefit analysis

- Landscaping studies and design

|

|

|

|

Water Resources

|

|

|

- Water resources investigations, planning and management

- Integrated water resources management (IWRM)

- River basin planning and management

- Water safety plan

- Dam break studies

|

|

|

|

Impact Assessment

|

|

|

- Environmental Impact Assessment (EIA)

- Environmental Management Report (EMP)

- Erosion and Sediment Control Plan (ESCP)

- Air, noise, vibration and water quality sampling and assessment

- Soil erosion and conservation studies

- Drought and flood risk assessment

- Health impact assessment

- Green technology solutions

- Risk assessment

- Land contamination assessment

|

|

|

|

Ecological Assessment

|

|

|

- Site assessment for ecological resources

- Flora and fauna studies

- Coral survey, mapping and reporting

- Ecological and biodiversity management and monitoring plans

- Protected area and wildlife management plans

|

|

|

|

Environmental Reporting and Auditing

|

|

|

- Environmental Management Plan (EMP)

- Environmental Monitoring Reporting

- Environmental Regulatory Compliance Audit

- Site Closure and Completion Plan

- Environmental Compliance Advisory

- Guided Self-Regulation (GSR) Implementation

|

|

|

|

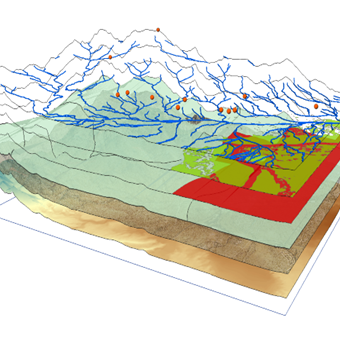

GIS Database and Analysis

|

|

|

- Digital mapping

- UAV / drone mapping

- Terrain and slope analysis

- GIS-based environmental analysis

- Support for environmental studies

|

|

|

|

Capacity Development and Training

|

|

|

- Environmental training, forums, seminars

- On-the-job, in-house and industrial training

- Capacity development partnerships with local and regional networks

- Education and awareness programmes

- Industrial mentorship programmes for academia

- Public outreach

|

|

|

|

|

|

Core Service

|

|

| |

Environmental Impact Assessment (EIA) |

|

|

| An Environmental Impact Assessment (EIA) can be described as a standard method to identify, predict, evaluate and mitigate the biophysical, social, and other appropriate effects of development proposals ahead of crucial decisions are taken and commitments are made. In short, EIA is a method of assessing the environmental impacts of a proposed project or development. |

|

| In project planning and design, EIA’s is utilized to predict environmental impacts at an early stage, find ways and means to reduce adverse impacts, shape projects to suit the local environment, and to present the predictions and options to decision-makers. |

|

| Our environmental Register EIA Consultant carry out Environmental Impact Assessment to achieve both environmental and economic benefits that include less cost and time of project implementation and design, avoiding treatment as well as clean-up costs and impacts of laws and regulations. The main goal of the EIA studies is to ensure that the decision maker considers the environmental impacts while deciding whether or not to proceed with a project. |

|

|

| |

Environmental Management Plan (EMP) |

|

|

| Environmental Management Plan (EMP) is a regulatory tool used to make sure that all the undue or reasonably avoidable adverse impacts of the construction, operation and decommissioning of a particular project are timely avoided, and that positive benefits of that project are substantially increased. |

|

| EMP includes four main features, namely commitment and policy, planning, implementation, and measurement and evaluation. It is considered as a vital tool which ensures that the management actions are clearly defined and implemented through all phases of the project life cycle. Environmental Management Plan is used as a vital tool to ensure that management actions are clearly defined and implemented through all phases of the project life cycle. |

|

|

| |

Environmental Compliance Audit (ECA) |

|

|

| Environmental Compliance Audit (ECA) is a systematic analysis of the compliance status of a facility and/or the extent of environmental liability. This process is a documented assessment of a facility, focusing on the present operating and administrative processes. |

|

|

| |

Environmental Modelling and Assessment (EMA) |

|

|

| Environmental Modelling and Assessment (EMA) allows a deeper understanding of the major processes and techniques to manage environmental changes. The assessment incorporates network monitoring design, sampling and related installation, and data analysis. |

|

| Environmental Modelling services ensure all the necessary support and tools required for mitigating risks and decreasing capital as well as operational expenditures by productive planning and environmental design. |

|

| we strongly believe that Environmental Modelling and Assessment can build bridges between the scientific community’s understanding of major environmental problems and the decision makers’ requirement to influence appropriate policies and regulations on the basis of the best available information. |

|

|

| |

Application of Written Notification & Written Declaration |

|

|

| Written Notification and Written Declaration are now part of the requirement in the Environmental Quality (Clean Air) Regulations, 2014. The Environmental Quality (Clean Air) Regulations 2014 replaced the Environmental Quality (Clean Air) Regulations 1978 and the Environmental Quality Regulations (Dioxin and Furan) 2004. Therefore, Written Approval (KB) for control system is no longer applicable. |

|

| In essence, the steps involved are: |

- Site visit with appointed registered engineer.

- Submit Written Notification ‘AS/PUB/N-CHIMNEY’ form to DOE.

- Installation of control system.

- Submit ‘Written Declaration on Design and Construction of Air Pollution Control System’ form with ‘As Built Drawing’ of the control system to DOE.

- Periodic/ continuous monitoring.

|

|

|

| |

Quantitative Risk Assessment (QRA) |

|

|

| Quantitative Risk Assessment (QRA) is a formal and systematic procedure of identifying and evaluating the potential hazards associated with the operations of an engineering process and to demonstrate the risk lies in the ALARP (“as low as reasonably practicable”). |

|

| QRA is usually implemented on the basis of major technical hazards leading to potential accident occurrences by using measurable, objective data to decide asset value, probability of loss, and associated risk. A quantitative risk assessment also helps make cost-effective decisions while managing the risks for the entire asset lifecycle. We have progressive experience in a wide variety of risk assessment and risk management applications. We have successfully carried out several risk assessments cases for various offshore and onshore oil and gas installations using very specialized software. |

|

|

| |

Environmental Quality Monitoring |

|

|

| Water Quality Monitoring |

| The objective of water quality monitoring which includes effluent, surface, marine and ground water, is to obtain quantitative information on the physical, chemical, and biological characteristics of water via statistical sampling. The water monitoring is conducted to determine the environmental state and analysis of temporal water quality trends. We help our clients identify any potential water quality issues and mitigate long-term risks though site-specific solutions that enables our clients to deliver their environmental and corporate social commitment. |

|

|

| Acoustics, Noise & Vibration Monitoring |

| Noise assessment is carried out to determine the amplitude (level) of noise caused by a development project during the construction and operational phase of a project. The noise level modelling at the boundaries of the project will determine the noise pollution impacting the communities around the project. |

|

| Applying up-to-date technology, our Seismograph is able to measure vibration level at any potentially unstable environmental spot, be it construction site, damn, railways, ship liners, airliners, roads, etc. The data logging capability allows us to monitor and record vibration level at any specified length of time. This vibration monitoring is mainly to satisfy requirement of Environmental Impact Assessment. Vibration level monitoring is also required by the ISO 6954 (for noise/ vibration on ship/ vessel), also by the International Maritime Organization. |

|

|

| Air Quality Assessment & Modelling |

| Air Quality Assessment & Modelling is carried out to determine the type of pollutant that will be produced as a result of certain types of projects especially industrial activities, and the spread of the pollutant from the source to the surrounding environment based on the wind speed and directions data. Air quality assessment helps determine the negative impacts on surround communities and develop necessary mitigation measures. |

|

| Selected procedures for the measurement and sampling of Ambient Air Quality have been accredited by the Department of Standard Malaysia. With latest asset acquisition, we are now capable of running multiple Ambient Air measurements simultaneously, saving clients’ time and money. |

|

|

| Air, Water and Noise Modelling |

| Environmental impact assessment and risk analysis studies often rely on environmental pollution models that measure the emission of chemicals, or biological materials, which may cause discomfort, disease, or death to humans, damage other living organisms such as fish, or damage the natural environment or built environment. The models cover a broad range of scales that can be tailored to a single or multiple sites depending on the project objectives. With experienced technical team, we able to provide modelling services that helps our clients to plan their projects well prior to its implementation to safeguard the environmental risks and proposed mitigation measures that will mostly affect their cost commitment needs. |

|

|

| Industrial Effluent Characteristic Study |

| Industrial Effluent Characteristic Study (IECS) is usually carried out to determine: |

|

- Current capacity of a Waste Water Treatment Plant or Sewage Treatment Plant.

- The necessity of an upgrading a Water Treatment Plant or Sewage Treatment Plant.

- Design and modelling of a new Water Treatment Plant or Sewage Treatment Plant.

- The necessity of building a Waste Water Treatment Plant or Sewage Treatment Plant.

|

|

| Industrial Effluent Characteristic Study will involve the qualitative and quantitative measurement of industrial influent and effluent which normally would take 24 hours over a period of three days. Methods of sampling during Industrial Effluent Characteristic Study will varies depending on flow condition at site. |

|

|

|